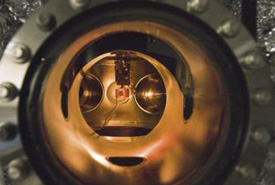

Thomas Electronics has provided Research & Development for a number of diverse areas including CRT displays, LCD, and deflection components. Our R&D programs have encompassed the following:

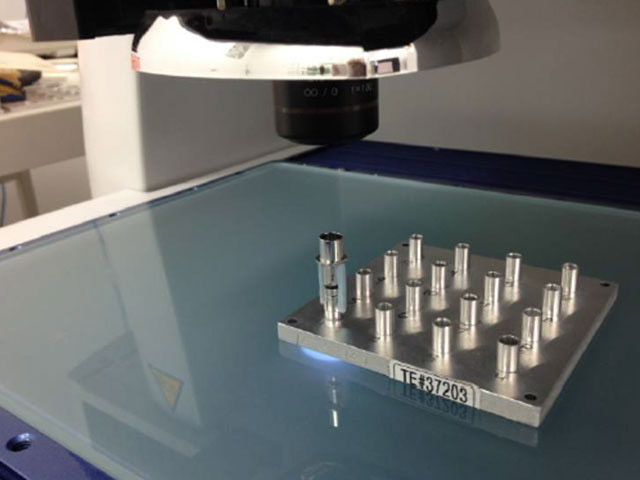

- Novel electron gun structures

- Fast phosphors for Telecine Applications

- Coatings for targets

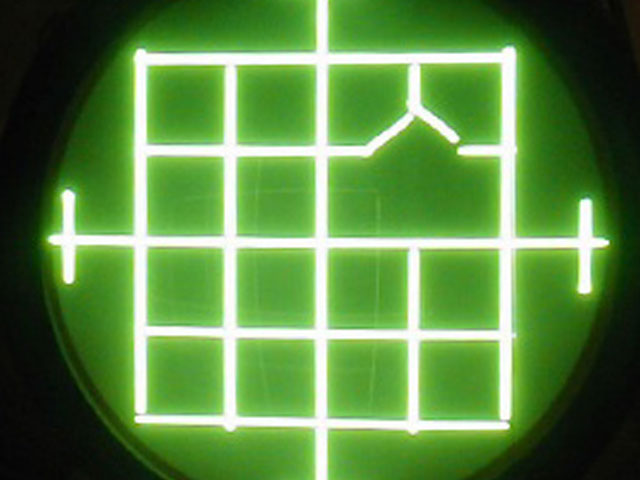

- Fast deflection components for high frequency scanning

- Flat Lamp development

- Photographic Exposure Devices

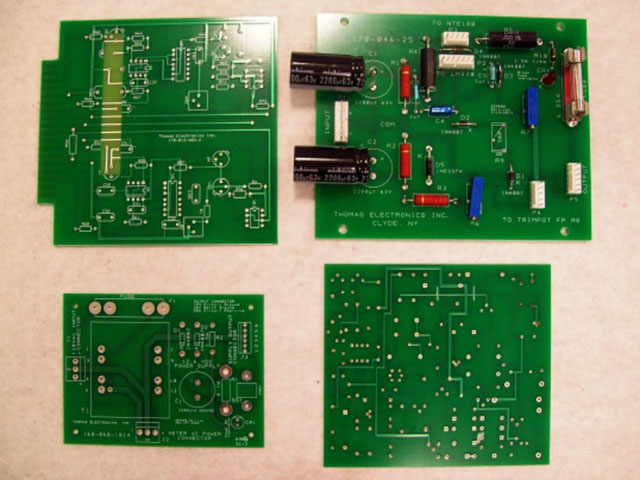

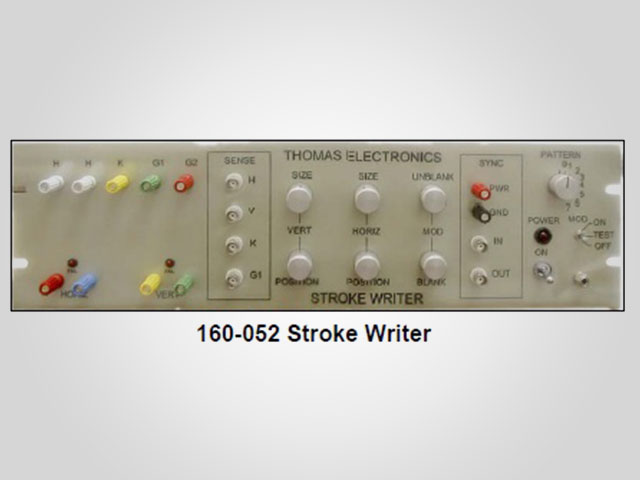

- Digital Beam Control

- Ceramic funnel materials for low profile CRT envelopes